Toilet Soap

- 3 lines to Manufacture 3 different brands at a time

- Adequate, Segregated and Safe Storage.

- Pressurised working area for dust free hygienic environment.

- PLC based controls.

- Imported equipment for critical areas.

- Vast Experience in manufacture of Soaps and Soap Products

New four-floor Building

- Gravity Flow of Material

- Problem Free Operation

- Spacious Work Area

- Ample Storage

Soap Plant - Boiling Section

Pan ( Kettle ) Boiling

Soap Plant - Finishing Section

- Pressurised working premises

- False Roofing and PVC Flooring

- Avoids Dust Ingress

Soap Plant - Finishing Section

- Double Sigma Mixer

- Proven MILINDIA Line Equipment

- Electronic Balances for Batching

Soap Plant - Finishing Section

- Refining Plodder

- Double Worm Plodders

- High Pressure Refining

- Homogenised Mixing

- VFD's for Plodders

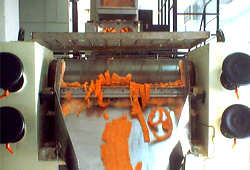

Soap Plant - Finishing Section

- Triple Roll Mill

- Proven MILINDIA Line Equipment

- Low Grit Soap

- Precise & Lockable Rollers Gap

- Adjustment

Soap Plant - Finishing Section

- Stamping M/C

- Supply by Mazzoni Italy

- Fully Automated

- PLC & VFD's for Better Control

- Dedicated Chilling Unit with Automated Control

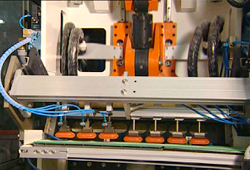

Soap Plant - Finishing Section

- STUR 7 Stamping M/C

- Closeup View

Soap Plant - Finishing Section

- STUR 7 Stamping M/C

- Closeup View

Soap Plant - Finishing Section

- Wrapping Machines

- Semi Automatic

- Online Metal Detectors

- In Process and Online QC